Vipal has announced the first two installations of its recently launched buffing machines, first introduced in 2016. The first installation of the dual position VR01 Smart Duo buffer was at Vipal authorised dealer União Tyre Retreading, a São Paulo retreader, in April this year. Soon after Toro Recauchutagem installed the VR01 Smart UNO, which has one buffer position, started to operate at its plant in Rio de Janeiro.

Brazilian Retreaders Have Installed a New Vipal Buffer

Founded in 1969, União is located in Rio das Pedras (São Paulo) in an area of 21,000 square metres, producing an average of 4,000 tyres/month, which cover the state of São Paulo and northern Paraná. The company has been a member of the Vipal Authorized Dealer Network since 2007.

Founded in 1987, Toro Recauchutagem operates repair with a wide and qualified line of raw material, machinery and labour. It has been a Vipal Authorized Dealer Network since 1997.

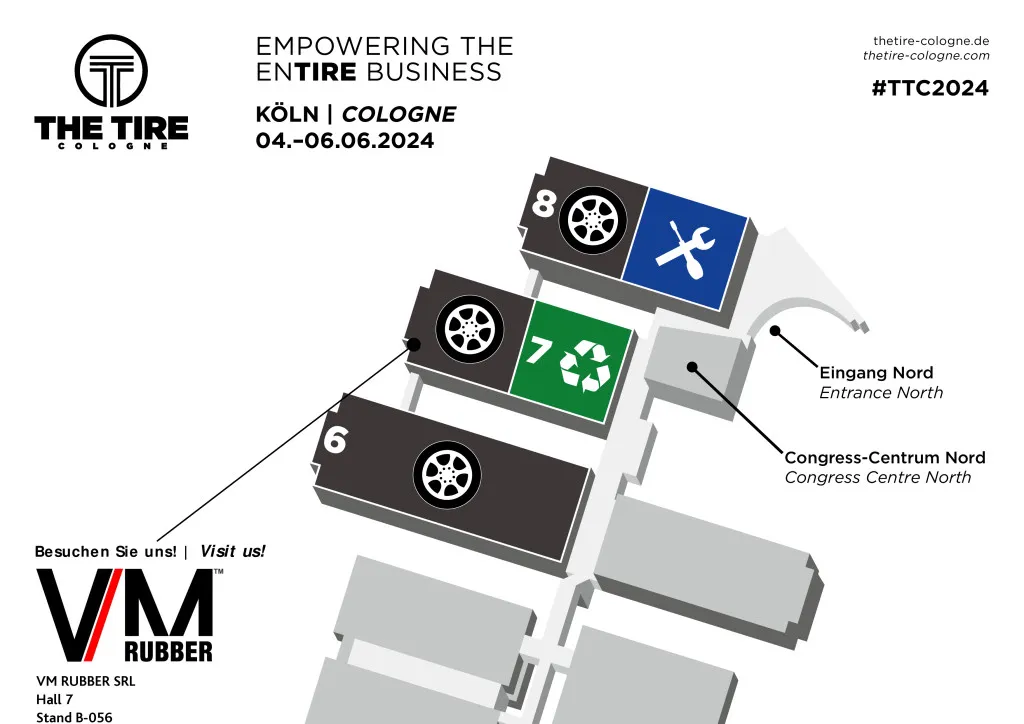

According to Dirceu Formaggio, director of União Tyre Retreading, productivity is expected to increase with the acquisition of the VR01 Smart DUO. “We intend to reach 30 tyres per hour, buffing around 200 tyres daily, which we believe will bring a lot of benefits to our production,” he said. For Toro, obtaining the equipment was also celebrated. According to Alcidio Morgado, director of Toro, the action is part of a very well structured strategy in partnership with Vipal Rubber to expand production and, consequently, the retreader’s target market. “Today we can say that the investment has exceeded expectations. I am very pleased with this new acquisition, and I am sure it will greatly improve our buffing process,” concluded Morgado.

“This is a pioneer project by Vipal, which demonstrates that we are always thinking about increasing the productivity of the retreading partners and improving the tyre retreading market” said Henrique Brito, Technology and Quality Manager at Vipal Rubber and coordinator of the innovation group that developed the equipment.

The VR01 Smart DUO, with two buffing positions, processes up to 35 tyres/hour. The VR01 Smart UNO has one buffing position and a production capacity of up to 28 tyres/hour. Both are claimed to have the highest productivity on the market compared to competitors. Launched in 2016, it is the first equipment developed for marketing by Vipal, which aims to offer to its network partners more competitiveness, efficiency and quality in the retreading process. With all project and execution developed by the company, the machine is 100% manufactured in Brazil and meets the requirements by the NR12. Also, it has onsite and online technical assistance from the largest tyre retreading technical team in Brazil.